This product is not exportable outside the United States.

By adding this item to cart, you agree and acknowledge the Export Policy and confirm that you are a person in the United States with no intentions to illegally export the device.

This product is not exportable outside the United States.

By adding this item to cart, you agree and acknowledge the Export Policy and confirm that you are a person in the United States with no intentions to illegally export the device.

0

0

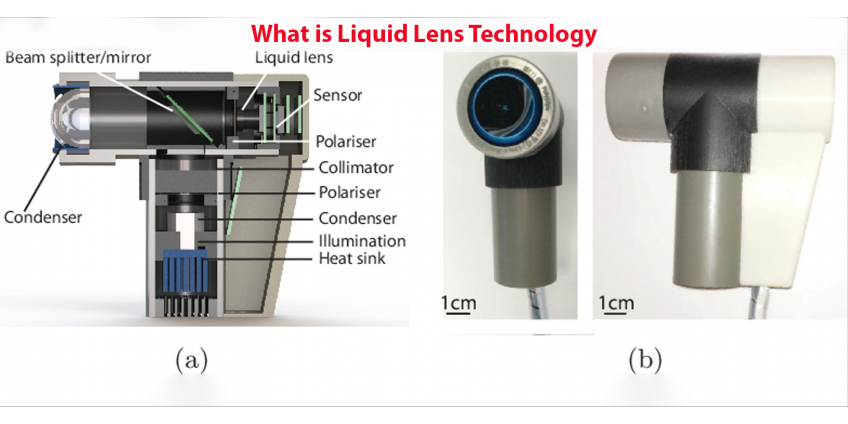

Nowadays, almost all technical optical devices use solid lens systems to achieve the desired effects, but it seems more advantageous to use a single liquid lens (LL) with variable focal length (VFR) instead of several conventional (solid) lenses, which will increase the efficiency and performance of the device and make production more economical.

Conventional lenses are the universal optical element of most optical systems.

Traditional applications for lenses include binoculars, telescopes, theodolites, microscopes and photovide technology.

Single assembly lenses are used as magnifying glasses.

Another important field of application of lenses is ophthalmology, where without them, it is impossible to correct vision deficiencies - myopia, hyperopia, incorrect accommodation, astigmatism and other diseases.

Lenses are used in such devices as glasses and contact lenses.

Radio astronomy and radars often use dielectric lenses that collect the flow of radio waves into the receiving antenna, or focus on the target.

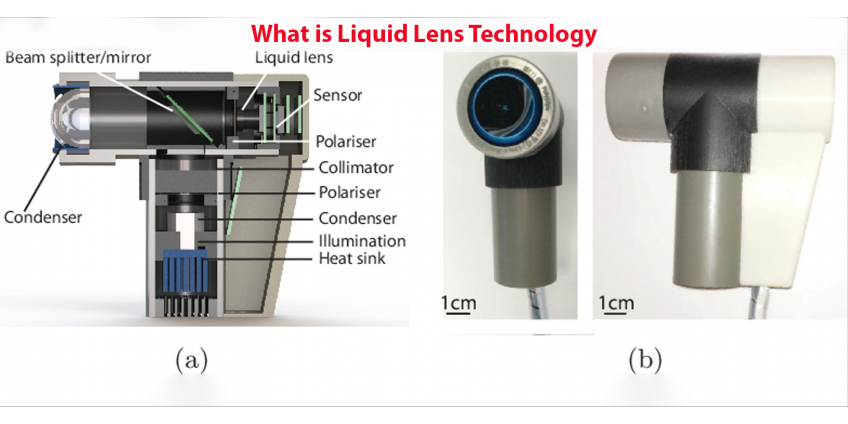

So far, the main limitation for liquid lens technology is the small size of the lens, which is about 7-10 mm: these lenses cannot be used for high quality photography. However, companies are working to increase the diameter of the lens and are also complicating the circuit by introducing a second liquid lens to support optical zoom.

Back in 2005, the head of the French innovation company Varioptic, Etienne Pillard, held a closed presentation of Electrowetting technology, which is based on liquid lens.

For this purpose, a drop of water (in fact, any conductive liquid can be used instead), "trapped" between two drops of hydrophobic oil. This "sandwich" consists of a thick shell made of glass or transparent plastic. Water and oil are not mixed, so no additional membranes are required to clearly separate the two liquids. Then a precisely controlled low tension is applied to the water - under the influence of this tension a drop of water changes its shape: the higher the tension, the more stretched it becomes. This lens has no moving parts, no need to heat or change the density of individual liquids.

As we know that the free surface of a liquid on the surface of a solid body can be curved. This is due to the wetting effect. If the liquid wetting the surface, the drop placed on the surface will flow over it. If the liquid does not wet the surface, its behavior will be different.

The value of the surface tension coefficient of the liquid, and therefore the degree of bending (radius of curvature) of the free surface of the liquid can be changed by adding the so-called surfactants. In addition, at the end of the19th century it was found that the value of the potential difference between the conductive surface and a drop of conductive liquid affects wetting: the edge angle decreases in proportion to the square of the voltage. This is the so-called electric wetting effect.

Let us place a drop of water on a super hydrophobic surface (i.e. the one that water does not wet at all) - it forms an almost perfect ball. Then apply a tension between the surface and the drop - the drop as if pressed against the surface, the edge angle will be reduced. Smoothly increasing and decreasing the tension, you can force the drop to change its curvature radius. The curvature of the drop surface changes, therefore the refractive power of the lens and its focal length also changes. There are no moving mechanical parts. The operation of a liquid lens is very similar to the human eye, which focuses by changing the curvature of the lens.

Liquid lenses, unlike conventional lenses, allow you to change both the sign of focal length and have a significant depth of adjustment of their focal length, ie, LL systems are able to change the optical characteristics without changing the distance between the lenses. Thus, the use of LLs in optical systems significantly extends the functionality of these systems in real time, which is important for adaptive optics.

Using LLs as lenses instead of solid-state lens systems in micro-cameras will reduce the size of the latter. This should also help to reduce energy consumption. Low power consumption, for example, will make it possible to efficiently use converters of free energy (acoustic, electromagnetic) distributed in space.

Thus, the main advantages of LVs are:

● A wide range of focal length adjustment;

● Easy handling as only the movement of the piston is necessary;

● Mobility, i.e. can be used from any angle;

● Simple - consisting of frame, water, piston, film;

● Cheap in manufacturing;

It is possible to use one lens instead of several conventional lenses (i.e. it is no longer necessary to move the lenses in relation to each other to change the focal length of the system, just to change the LL parameters);

● Simulation of the human lens;

● No harm to the environment in case of damage or disposal;

Automation of the lens control process, i.e. control of the lens by computer via servo drives, controllers, etc. is possible;

● The LC design allows the surface curvature to be maintained, i.e. the piston does not "spontaneously" shift after the lens volume has changed;

● All lens types can be created;

● Operates with relatively large entrance pupil diameters;

● The LC also enhances adaptive optics, so you do not have to move the lenses around to change the parameters of the optical system, but you can change the lens characteristics in real time.

Liquid lenses have all kinds of applications:

● Creation of glasses with variable focal lengths;

● Focusing light in lanterns, spotlights, car headlights;

Creation of telescopes, binoculars, magnifying glasses, optical tubes, microscopes, photo and video cameras;

● Simulation of human lens and use for creation of robots;

● Creation of artificial "eyes" capable of seeing in different spectra;

● Creation of training glasses for training and vision correction in children and adults;

● Use of LVs for navigation systems (rockets, airplanes, etc.);

● On satellites in earth orbit or near planetary orbit, i.e. in conditions of low gravity.

Use in all areas where conventional lenses operate and the laws of geometric optics are followed.

In recent years, several large IT and video companies have become interested in liquid lenses. In particular, Philips has announced the Fluid Focus optical system, which works by changing the electrical potential applied to the hydrophobic coating. The size of Fluid Focus prototype was a few millimeters, the focal length adjustment was in the range from 5 centimeters to infinity, with the adjustment speed between the extreme positions of less than 10 milliseconds. Bell Labs, Varioptic, etc. also develop systems like Fluid Focus.

Table of contents

Featured Articles

You've probably heard about scientists inventing lenses for night vision. In this article, we will tell you about this technology and how it works...